|

Home

Residential

Commercial

Cooling Towers

Demand-Buster

HVAC Chillers

Performance

Contact Us

| |

|

|

Thermal~Flow Cooling Towers

|

|

Thermal~Flow Evaporative Condensers and Closed Circuit Cooling Towers

Thermal~Flow's innovative Evaporative

Condenser (TFEC) and our Closed Circuit Cooling Tower (TFCCT)

use advanced coil technology

which reduces the tendency to accumulate scale

on the coil surface. Scale is the build-up

of solids, often calcium and magnesium compounds,

resulting from the evaporation of water directly on the

condenser tube bundle within the unit.

By reducing scale tendency, peak heat transfer capability is

sustained over the life of the equipment and coil

longevity is maximize. Thermal~Flow Cooling Towers save customers time, money

and energy during the installation, operation and

routine maintenance.

|

Proven Commercial Water Cooled

Technology

Requires no Structural

Roof Upgrades

Engineered for Commercial

Roof-Top Applications

Light Weight, Modular,

Durable, Low Maintenance

Proven Record of Operational

Success

15 Year Limited Warranty

|

|

|

Thermal~Flow has combined it's superior TFEC Evaporative Condenser

with the newest Scroll compressor technology, and the most efficient

fans, pumps, and heat exchangers available to produce it's

Ultra-Efficient HVAC Multi-Stage Packaged Chillers, Demand-Buster 50-Ton 4-Pipe HVAC, and our Residential Water Cooled Air Conditioner Systems.

The Thermal~Flow Closed Circuit Cooling Tower is the heart of the Demand-Buster HVAC Retrofit System,

Hybrid Geothermal Systems, and Water Cooled Commercial Chillers. They

are also perfectly suited to many waste heat applications that call for

high efficiency fluid coolers. The four unique design features of Thermal~Flow's Cooling Tower with advanced coil

technology contribute to the reduced propensity

to scale, and lower energy consumption:

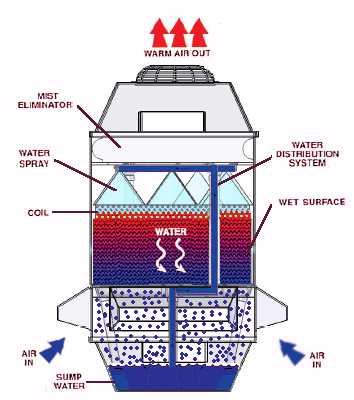

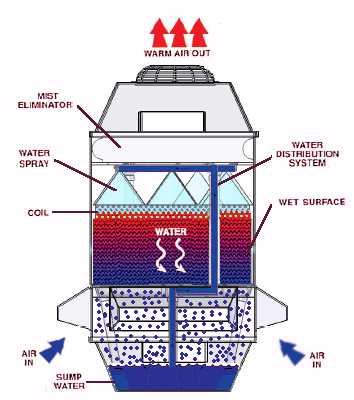

1. Low Velocity Updraft Air Flow: Improved

water coverage around the tubes is due to lower air flow

in an updraft path over the evaporative condenser coil,

maintaining full tube coverage. With lower air flow,

velocity the spray water is not stripped from the

underside of the tubes by the airflow; thus

eliminating scale-promoting dry spots.

|

|

|

2. Increased Water Flow Over Coil: The over-lapping

coverage of the non fouling spray nozels along with a water flow rate

over the coil area that is more than a conventional

evaporative condenser is unique to the TFEC.

This provides continuous flooding of the primary heat transfer surface for

decreased scaling potential.

3. Evaporative Cooling Occurs Primarily in Evaporative Media:

The TFEC Evaporative Condenser incorporates

advanced technology using both primary and secondary heat transfer surfaces.

The primary heat transfer surface, the serpentine

evaporative condenser coil, is the most important as well as

the most expensive component in the evaporative

condenser. The coil of the TFEC is protected from

detrimental scale since it relies primarily on

sensible heat transfer and therefore is less susceptible

to scale formation than are other designs that rely

primarily on latent (evaporative) heat transfer.

The technology behind the secondary heat

transfer surface, the PVC wet media, has been

proven scale

|

Thermal~Flow TFEC Operation Principals

Thermal~Flow TFEC Operation Principals

|

|

|

resistant and durable for more than

30 years in cooling tower applications. More than

80% of the latent heat transfer occurs in the

secondary surface, moving the evaporation away

from the primary heat transfer surface.

4. Colder Spray Water: Spray water at colder

temperatures has a lower propensity to form scale

because scaling compounds remain in solution rather

than depositing as solids on the evaporative condenser coil. In the TFEC the

spray water over the coil is colder than other evaporative condenser designs due to the

addition of the secondary heat transfer surface. The

colder spray water alone reduces the scaling

potential by 25% compared to other

designs.This is above and beyond the reduction

achieved by Thermal~Flow's our other three unique design features

Thermal~Flow Evaporative Condenser Tower

|

- Construction: All fiberglass cabinet, cannot corrode. High quality materials throughout.

High efficiency evaporative condenser design.

- Water Spray Nozzles: Durable plastic, non-corrosive and

non-fouling.

- Fans:

Aluminum body, High Efficiency multi-speed fan motors, epoxy coated

frame,precision balanced plastic blades for quiet, trouble-free

service.

- Service: Easy access for routine maintenance

|

Thermal~Flow 30-Ton Evaporative Condenser

Thermal~Flow 30-Ton Evaporative Condenser

|

^ back to the top ^

|

Thermal~Flow 30-Ton Evaporative Condenser

Thermal~Flow 30-Ton Evaporative Condenser